Modern Modular Home Designs in America: Options and Layouts

Factory-built housing has moved far beyond the boxy stereotype. In the United States, modern modular and other prefab approaches can offer flexible layouts, tighter quality control, and shorter build timelines than many site-built projects. Understanding the main prefab categories, the design process, and realistic cost drivers can help you evaluate whether this construction method fits your goals and local requirements.

Across the United States, more buyers are looking at factory-built construction as a practical way to get contemporary layouts without starting from a fully custom, on-site build. Modern modular home designs can range from compact ADU-style footprints to multi-section family homes with open living areas, large windows, and energy-efficient assemblies. The right choice depends on how the home is produced, how it is delivered and assembled, and how well the design matches your land, climate, and local building rules.

How do prefab homes work?

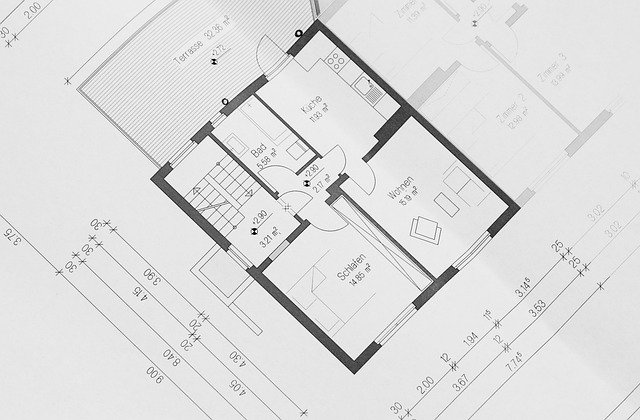

Prefab homes are built partly or mostly in a factory setting and then transported to the homesite for final installation. The broad idea is consistent, but the workflow varies by type: modular homes are typically built in large sections (modules) that are set on a foundation; panelized homes ship as wall, floor, and roof panels for on-site assembly; and manufactured homes are built on a permanent chassis and installed according to federal HUD standards rather than local site-built codes. In most cases, the process includes design and engineering, factory production, transportation logistics, on-site foundation work, setting/assembly, and finishing steps like utility hookups and interior trim.

What are the benefits of prefab homes?

Efficiency is often the biggest practical advantage. Factory conditions can reduce weather delays, improve material storage, and support repeatable quality checks, which may help with consistency across builds. Speed can improve because site work (like foundations and utilities) can happen while the home is being produced. Many projects also see less material waste due to standardized cutting and inventory practices, although results vary by manufacturer and design complexity. Affordability can be a benefit in some scenarios, but it is not automatic; total cost depends on land, site conditions, finishes, transportation distance, and local labor rates.

Prefab vs. traditional building: key differences

Prefab construction can be faster and more predictable on the schedule side, but it introduces constraints that traditional building may not. Module sizes must fit transportation rules and routes, which can influence ceiling heights, spans, roof shapes, and even window dimensions in some designs. Traditional site-built homes can be easier to adjust mid-build, while prefab projects typically lock key decisions earlier to keep factory production on track. Sustainability comparisons also depend on specifics: prefab methods may reduce waste and site disturbance, yet transportation and crane use can add emissions and logistics costs. Building-code pathways differ as well, especially between modular (local codes, factory inspection) and manufactured homes (HUD code).

Modern prefab designs: modular vs. manufactured

Layout options have expanded significantly. Modular homes commonly support open-concept kitchens and living areas, split-bedroom plans for privacy, and add-on modules for home offices, mudrooms, or expanded primary suites. Panelized systems can be useful for modern architecture with large glazing areas and vaulted ceilings, especially when paired with engineered roof systems. Manufactured homes often provide efficient single-level layouts and can include upgraded finishes, but their siting rules, financing options, and long-term appreciation patterns may differ by region and property type. Across categories, pay attention to “design flexibility” in practice: some builders offer semi-custom plans with configurable kitchens and baths, while others operate with fixed models to keep pricing and timelines stable.

How cost-effective is prefab housing in the U.S.?

Costs are highly project-specific, so it helps to separate the factory-built portion from the full, move-in-ready budget. A realistic estimate should include the home package (modules/panels), delivery, crane or set fees (for modular), site preparation, foundation, utility connections, permits, and finish selections. Land and site conditions can dominate total cost: sloped lots, long driveways, difficult soil, remote access, septic and well requirements, and stricter local codes can all add meaningful expense. For apples-to-apples comparisons, ask for a “turnkey” estimate and a clear list of exclusions.

| Product/Service | Provider | Cost Estimation |

|---|---|---|

| Manufactured home (single-section) | Clayton Homes | Often quoted as a lower-cost entry option; total installed cost varies widely by region, land, and setup. |

| Manufactured home (multi-section) | Cavco Industries (brands vary by region) | Mid-range for manufactured housing; pricing depends on size, options, and local setup requirements. |

| Modular home (plan-based) | Skyline Champion (regional builders/brands) | Commonly priced by plan and specifications; site work, transport, and set fees can be significant. |

| Panelized home package | Stillwater Dwellings | Package pricing varies by model and scope; site-built labor and local trades affect totals. |

| Modular/panelized modern home | Method Homes | Frequently priced by design/spec level; final costs depend on site conditions and finishes. |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

A practical way to evaluate cost-effectiveness is to request a detailed scope sheet: what is included in the base model (appliances, cabinetry grade, windows, HVAC), what is optional, and what is excluded (permits, foundation, driveway, landscaping, utility trenching). Financing can also change the picture. Some prefab categories align more easily with conventional mortgage pathways than others, and lender requirements may affect timelines and cash needed upfront. Finally, schedule savings can translate into lower carrying costs (like rent during construction), but only if the project avoids redesigns and site surprises.

Modern modular home designs in America can offer a compelling mix of layout flexibility, factory-driven consistency, and potentially shorter timelines, but the right outcome depends on matching the prefab type to your land, local regulations, and expectations around customization. By focusing on how the home is built and delivered, comparing prefab vs. traditional tradeoffs honestly, and budgeting for full installed costs rather than the headline “home price,” you can assess options and layouts with a clearer view of what will work in your area.